Explain the production process of environmentally friendly P

欄目:Industry News 發(fā)布時間:2021-06-03 15:19

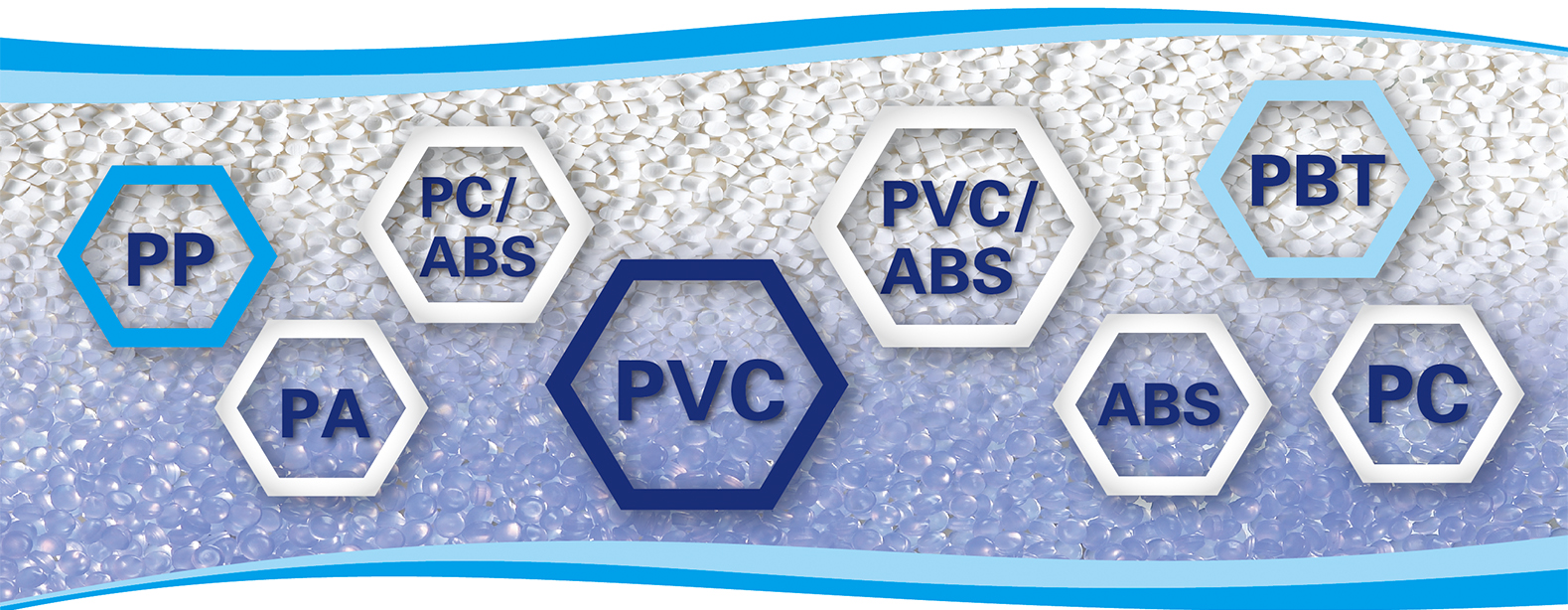

As a novel synthetic material, toy PVC granules are widely used in the manufacture of various toys. Because PVC is a kind of non-crystalline material, it is not easy to burn, resist oxidation and high strength, so it is very suitable as a pr...

As a novel synthetic material, toy PVC granules are widely used in the manufacture of various toys. Because PVC is a kind of non-crystalline material, it is not easy to burn, resist oxidation and high strength, so it is very suitable as a production material for children's toys. From radios to guns and rockets, from flowers and insects to cartoon characters, colorful and varied, it has formed a dynamic world of modern plastic toys. Below we will specifically talk about the production process of toy PVC granules.

Toy PVC granules usually have two forms of presence: powdered and granulated. Compared to powder, granular processing has the following advantages:

1. The relative density of PVC granules is larger than that of powdered materials, and the strength of plastic products is better.

2, convenient feeding, do not need to install a forced feeder in the hopper.

3. The mixing of PVC resin with various solid powder materials or liquid additives is relatively uniform, and the physical properties of plastic products are better.

4, granular toy PVC granules containing less airborne volatiles, so that plastic products are not easy to produce bubbles.

5. Extrusion granulation is a basic and simple granulation method. The hard PVC granules have no pollution to the extruder and production environment.

The advantages of PVC granules are very high, which is more conducive to our production and processing. The production process of toy PVC granules is as follows:

1. Preparation before the ingredients. The preparation work before the general ingredients includes a plurality of processes such as resin sieving, plasticizer filtration, powdery additive refining, preparation of color masterbatch powder, and heating, melting and drying of the block additive.

2. After the preparation is completed, the formula needs to be weighed. According to the volume of the equipment and the feed coefficient, the amount of feed is estimated and mixed to obtain the raw material for mastication.

3. Kneading. The toy PVC granules can be heated and kneaded or cooled and kneaded by a high-speed kneading machine.

4. Extrusion granulation. Both single-screw and twin-screw machines can be used for extrusion granulation, which requires control of extrusion temperature, cutter speed, and pellet cooling. The size and size of the particles are made uniform, the granules are not sticky, and the plasticization property is good.

The above is the specific process of the production process of toy PVC granules. Toy PVC granules have a wide variety, diverse performance and simple processing, providing an ideal plastic material for the manufacture of modern toys.

Wuxi Jiahong Plastics Technology Co., Ltd. has nearly 30 years of experience in research and development and granulation of modified PVC granules. The professional technical service team can provide one-stop system solutions for customers. For more information about the product, please visit our official website: www.yfztp.cn, consult online customer service or call the hotline. Fixed line: 0510-68755207 Mobile: 15190220696, we will be happy to help you.

(Disclaimer: All the tutorials and resources included in this site are from the Internet, and the copyrights are owned by the original author and its website. Although this site strives to preserve the original copyright information, it may not be possible for certain reasons. For the true source, please forgive the original author! If you have any objection to the attribution of the tutorial and resources on this site, please notify Xiaobian immediately, the situation is true, we will delete it as soon as possible.)

人妻夜夜爽天天爽精品三区|

亚洲高潮久久久久久|

欧美亚洲另类在线第一页|

色狠狠av一区二区三区香蕉|

久久久久久精品免费看|

午夜精品久久久久久久久久久|

av中国一区二区三区|

国产欧美精品区一区二区三区竹菊|

盗盗摄婷婷精品一区二区|

亚洲欧美国产其他二区|

丰满少妇爽视频一区二区三区|

亚洲国产成人精品女人久久0|

国产美女高潮抽搐流水在线看|

911国产精品视频|

久久久久国产精品熟女影院|

花花草草寻亲记哪里看全集|

日本成人免费一区二区三区|

成人亚洲精品一区二区|

欧美日本大陆一区二区|

五月婷婷六月丁香免费视频|

久久久精品视频免费在线|

中文字幕视频一区人妻|

精品视频一区二区三区美女视频|

国产精品一区二区30p|

1024欧美一区二区三区人妻|

亚洲国产精品久久久久av|

国产精品va在线观看老妇女|

日韩精品一区二区三区高清免费|

欧洲在线观看亚洲三区|

亚洲av乱码一区二区三区女|

亚洲国产成人久久精品不卡|

中文字幕日韩在线高清欧美|

久久久久久国产综合精品|

91精品国产综合久久久福利|

黑人操亚洲女一级黄色片|

日本色一区二区三区四区五区|

久久亚洲国产精品五月天|

呦男呦女视频精品八区|

国产精品一区二区三区三级天堂|

国产精品23一区二区|

激情综合婷婷丁香五月俺来也|

Toy PVC granules usually have two forms of presence: powdered and granulated. Compared to powder, granular processing has the following advantages:

1. The relative density of PVC granules is larger than that of powdered materials, and the strength of plastic products is better.

2, convenient feeding, do not need to install a forced feeder in the hopper.

3. The mixing of PVC resin with various solid powder materials or liquid additives is relatively uniform, and the physical properties of plastic products are better.

4, granular toy PVC granules containing less airborne volatiles, so that plastic products are not easy to produce bubbles.

5. Extrusion granulation is a basic and simple granulation method. The hard PVC granules have no pollution to the extruder and production environment.

The advantages of PVC granules are very high, which is more conducive to our production and processing. The production process of toy PVC granules is as follows:

1. Preparation before the ingredients. The preparation work before the general ingredients includes a plurality of processes such as resin sieving, plasticizer filtration, powdery additive refining, preparation of color masterbatch powder, and heating, melting and drying of the block additive.

2. After the preparation is completed, the formula needs to be weighed. According to the volume of the equipment and the feed coefficient, the amount of feed is estimated and mixed to obtain the raw material for mastication.

3. Kneading. The toy PVC granules can be heated and kneaded or cooled and kneaded by a high-speed kneading machine.

4. Extrusion granulation. Both single-screw and twin-screw machines can be used for extrusion granulation, which requires control of extrusion temperature, cutter speed, and pellet cooling. The size and size of the particles are made uniform, the granules are not sticky, and the plasticization property is good.

The above is the specific process of the production process of toy PVC granules. Toy PVC granules have a wide variety, diverse performance and simple processing, providing an ideal plastic material for the manufacture of modern toys.

Wuxi Jiahong Plastics Technology Co., Ltd. has nearly 30 years of experience in research and development and granulation of modified PVC granules. The professional technical service team can provide one-stop system solutions for customers. For more information about the product, please visit our official website: www.yfztp.cn, consult online customer service or call the hotline. Fixed line: 0510-68755207 Mobile: 15190220696, we will be happy to help you.

(Disclaimer: All the tutorials and resources included in this site are from the Internet, and the copyrights are owned by the original author and its website. Although this site strives to preserve the original copyright information, it may not be possible for certain reasons. For the true source, please forgive the original author! If you have any objection to the attribution of the tutorial and resources on this site, please notify Xiaobian immediately, the situation is true, we will delete it as soon as possible.)